Safety analysis of high-pressure booster oxygen compressor

This article makes a comprehensive analysis and evaluation for the design and safety use of the ultra-high pressure oxygen compression filling system, and proposes measures to prevent explosion accidents.

Material combustion has three necessary conditions: combustible material, combustion-supporting material and combustion temperature (ignition source). Oxygen is one of the most common combustion-supporting substances (oxidants). This system is used to make, store and transport high-purity oxygen. Therefore, to prevent explosion occur, measures must be taken from both combustibles and combustion temperature.

Safety design of high-pressure oxygen compressor and filling system

Oxygen is a strong oxidant, which is easy to react with other substances and cause fire. Therefore, in addition to the general rules and regulations of safe gas compression and filling such as air and nitrogen, the process of oxygen compression and filling must also pay attention to the prevention of explosion.

Aspects of safety design:

1. The safety design of the compressor structure

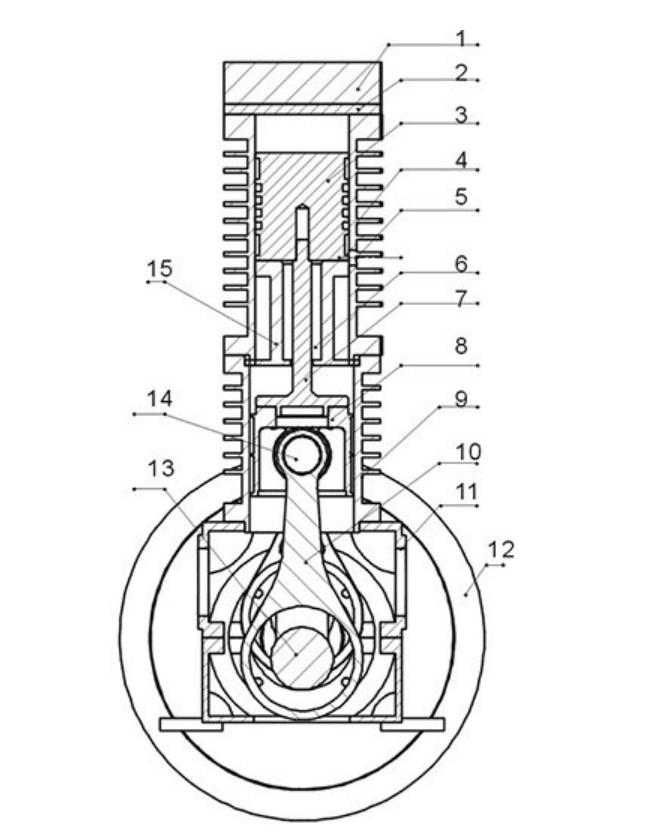

It adopts all oil-free lubrication reciprocating piston compressor.

See from above drawing, we can know that the compressor's motion mechanism, such as the rotation of the crankshaft connecting rod, the reciprocating linear motion of the guide piston and the piston, does not require additional thin oil lubrication. This compressor uses sealed grease lubricated bearings for rotary motion and self-lubricating materials for reciprocating motion. There is no dilute lubricating oil in the compressor body, and the sealed bearing adopts anti-oxidation perfluorinated grease.

Because the high temperature and high pressure oxygen and oil contact will cause a great reaction, the compressor is completely oil-free, which greatly reduces the possibility of explosion accidents and lays the foundation for the safe use of the compressor.

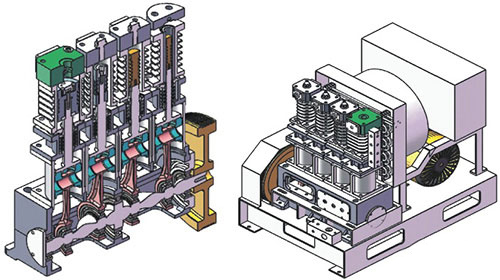

The compressor adopts a four-row vertical structure, every stage cylinder are gathered together, and an external fan is used for blowing and heat exchange. The heat exchange is sufficient, and the temperature of the oxygen compression process is controlled at a lower level. The appearance of the compressor is shown in the figure below:

The theoretical exhaust temperature at all levels is not more than 130°C, and the actual control is within 100°C. In order to ensure the reliability and safety of compressor performance, the compressor is designed with a low speed method. The theoretical calculation speed is 200 rpm. The extremely low speed prolongs the service life of wearing parts and ensures the safe operation of the compressor.

The speed of the gas medium compressed in the compressor not only affects the efficiency of the compressor, but for the oxygen medium, too fast flow rate can also cause the compressor to explode. Therefore, the oxygen flow rate in each pipeline of the compressor Select strictly according to the allowable flow rate in the tube. According to the compressor design manual, the specific flow rate values are as follows:

|

Pressure / MPa |

≤0.6 |

0.6 - 1.0 |

1.0 - 3.0 |

|

Flow Rate / m/s |

7- 8 |

6 - 4 |

4 - 3 |

According to this, the pressure of the high-pressure compressor is at 30Mpa, and the airflow design flow rate is 0.07s/m.

2. Safety materials of oxygen compressor

Oxygen can chemically react with many substances. Therefore, the parts of the compressor in contact with high-purity oxygen must be chemically inert. Therefore, the compressor cylinder, valve, cylinder head, pipeline and other materials are all made of stainless steel with low carbon content; the compressor’s piston, due to the compressor’s structure requires aluminum alloy and copper alloy, these materials conduct heat quickly, and does not produce sparks when friction occur. The piston ring and supporting ring of the compressor are made of polytetrafluoroethylene, which is known as the king of plastics, which is resistant to strong acids and alkalis and does not oxidize. The static sealing ring of the compressor adopts a fluorine rubber O-ring with excellent chemical stability; the thread sealing of the compressor adopts PTFE raw material tape, which has good sealing effect and resistance to aging.

The pressure-bearing parts of the compressor are subjected to a hydraulic test at 1.5 times the working pressure. The compressor gas pipeline has a moderate wall thickness and can withstand the corresponding gas pressure. If the high-pressure pipeline is welded, it shall be inspected by radiographic inspection.

3. Safety protection design of oxygen compressor

In order to ensure the safe operation of the compressor, safety valves are installed at all levels. When the inter-stage pressure exceeds its set value, the safety valves are opened to release the pressure in the compressor compression chamber and pipeline.

Each level is equipped with temperature display, and the final level is equipped with a forced shutdown if the temperature exceeds the standard.

Forced shutdown due to fan failure.

The compressor motor is set to overload and stop.

The compressor is equipped with low intake pressure protection. When the intake pressure is lower than the set value, the compressor stops.

The compressor is equipped with discharge pressure protection. When the discharge pressure is higher than 30.0MPa, the compressor will stop.

The compressor intake and exhaust at all levels are equipped with filters to prevent solid particles from moving and rubbing in the airflow and causing explosion.

The compressor rotating pulley and heat exchange fan are equipped with protective nets or protective covers to protect people.

Categories

latest blog

© Copyright: 2026 Aircompsupplier All Rights Reserved.

IPv6 network supported

Friendly Links :

Solar Pile Driver