Method and steps for adjusting rotor clearance of screw compressor

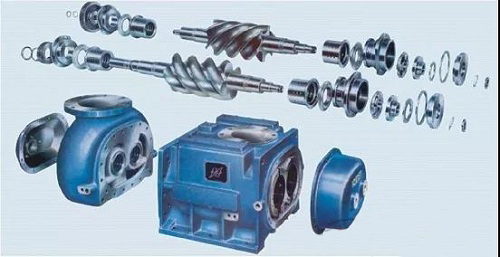

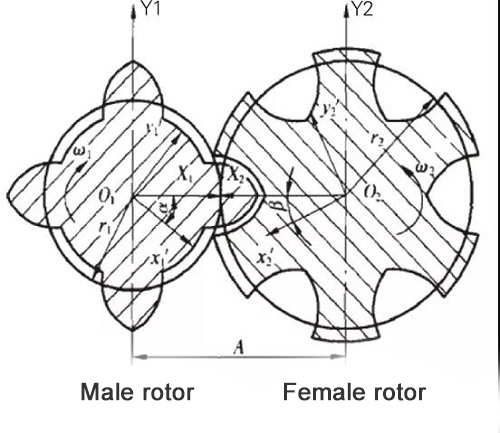

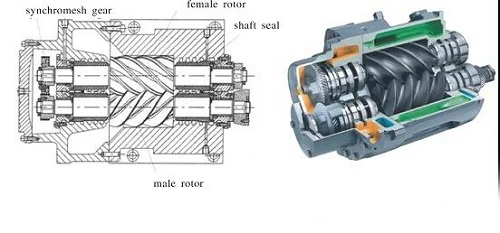

The maintenance of screw air compressor bearings, shaft seals and other components is roughly the same as that of centrifugal compressors. The core point of the maintenance is to adjust and control the ratio of the female and male rotor meshing gaps through synchronous gears. The female and male rotors of screw compressors are actually a pair of helical gears that mesh with each other. Therefore, the synchronous gear and the screw rotor are considered as an integral part. Based on the theory of conjugate gear meshing in gear transmission, the female and male rotors are changed. In order to realize the adjustment of the meshing gap ratio of the screw compressor rotor.

Gap design

When the screw compressor is working, the motor drives the rotor to rotate at a high speed, and the two end faces of the compressor casing are stationary parts, there must be a certain end face gap between them, and the end face that needs to be adjusted as the power of the screw compressor increases . The gap will also increase. When assembling the screw compressor rotor, a very important step is to adjust the clearance of the discharge end face. The adjustment will reduce the compressor displacement. If the adjustment is small, it is easy to cause friction between the rotor and the discharge end face. Therefore, the size of the screw compressor discharge end face clearance is determined by the designer based on actual engineering experience.

Generally, the clearance of the discharge end face of a screw compressor is comprehensively determined according to factors such as the size of the compressor power, operating conditions, and the material of the rotor and its cylinder. As long as the clearance of the discharge end face of the screw compressor is changed within a certain range, the normal operation of the compressor can be ensured.

Implementation steps

Loosen the fastening bolts and positioning pins between the driven gear ring and the wheel to make it flexible. The female and male rotors are brought into close contact by turning, and the total gap between the female and male rotors is accurately measured. Use the desired clearance value and the total clearance to calculate the difference of the chasing surface clearance, and then clamp the feeler gauge with the same or similar difference to the chasing surface clearance in the meshing area of the chasing surface of the female and male rotors by turning. During adjustment, a copper rod can be used to hit the screw on the synchronization gear until the feeler gauge is compressed and stopped.

Turn the driven gear ring to the position just meshing with the driving gear. Note that if necessary, the gear backlash can be completely placed on the side of the meshing teeth, and tighten the fastening bolts between the driven gear ring and the hub. Take out the feeler gauge between the female and male rotors. The gap at this time is the tooth surface meshing gap of the female and male rotors. However, in order to get up safely, you need to use the feeler gauge to check one by one while turning, and carefully measure the meshing of each part of the rotor and gap.

The total meshing gap between the female and male rotors of the screw compressor is large, so the adjustable range of the device gap ratio is large. Generally speaking, the screw compressor clearance ratio should be controlled between 0.8 and 1.2 filaments. In fact, when the screw compressor rotates at high speed, due to factors such as the thermal deformation of the tooth profile and the wear of the gear tooth surface, the chasing clearance tends to decrease, and the non chasing clearance tends to increase. In order to ensure the reliable operation of the compressor for a long time, the chase clearance should be increased during maintenance, and the non chasing clearance should be adjusted smaller, so that the ratio of chasing clearance to non chasing clearance is between 1.0 and 1.2.

The adjustment of the meshing gap of the screw compressor is the most critical step in the entire maintenance. It is directly related to the normal operation of the screw compressor. It is a difficult task and sometimes requires repeated adjustments to meet the requirements. The above is different from the traditional thinking, adopting the reverse idea, pre-specifying the initial phase of the rotor, and then adjusting the meshing gap between the driven gear ring and the driving gear ring and fixing it with fastening bolts. Under normal circumstances, this method can directly obtain the screw compressor meshing gap that meets the requirements, reducing the time for repeated measurement of the gap and adjusting the driven ring gear, and effectively shortening the maintenance cycle.

Categories

latest blog

© Copyright: 2026 Aircompsupplier All Rights Reserved.

IPv6 network supported

Friendly Links :

Solar Pile Driver