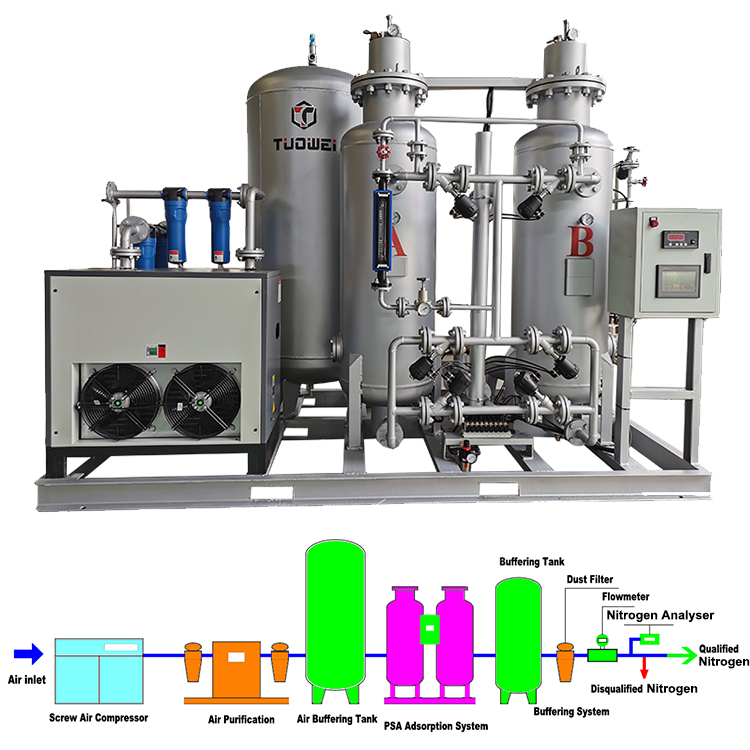

PSA(Pressure Swing Adsorption) is an advanced gas separation technology, based on the physical adsorption of the internal surface in the internal surface in the adsorbent to gas molecules, separating the gas by the characteristics of absorbing to the quantity of different gas in general pressure.

PSA nitrogen generator produces Na gas, using air as raw materials and carbon molecular sieve as adsorbent, by the selective adsorption of carbon molecular sieve to O2 and Nz, achieving the separation of the Nz and O2 in the air.

98% ~ 99.999% High Purity Nitrogen Generator

Product Details:

Product Specifications:

| Model | N2 flow | N2 purity | N2 outlet pressure | Motor power of matching screw air compressor | Air consumption | Inlet and outlet pipe dia | |

|

|

m3/h | % | bar | kW / 8bar | ≥ m3/min | mm | |

| SPN-5 | 5 | 99.50% | 3-6 (inlet compressed air at 7bar) | 7.5 | 0.24 | DN15 | DN15 |

| SPN-10 | 10 | 7.5 | 0.47 | DN15 | DN15 | ||

| SPN-20 | 20 | 7.5 | 0.94 | DN25 | DN25 | ||

| SPN-30 | 30 | 11 | 1.41 | DN25 | DN25 | ||

| SPN-40 | 40 | 15 | 1.88 | DN32 | DN25 | ||

| SPN-60 | 60 | 18 | 2.82 | DN32 | DN40 | ||

| SPN-80 | 80 | 22 | 3.76 | DN40 | DN40 | ||

| SPN-100 | 100 | 30 | 4.70 | DN40 | DN40 | ||

| SPN-120 | 120 | 37 | 5.64 | DN40 | DN50 | ||

| SPN-160 | 160 | 45 | 7.05 | DN50 | DN50 | ||

| SPN-200 | 200 | 55 | 9.40 | DN5D | DN50 | ||

| SPN-300 | 300 | 90 | 14.10 | DN65 | DN50 | ||

| SPN-400 | 400 | 110 | 18.80 | DN65 | DN50 | ||

| SPN-500 | 500 | 160 | 28.20 | DN80 | DN50 | ||

| SPN-800 | 800 | 200 2-stages compression | 37.60 | DN100 | DN65 | ||

| SPN-1000 | 1000 | 220 2-stages compression | 47.00 | DN100 | DN80 | ||

| SPN-1200 | 1200 |

|

56.40 | DN125 | DN80 | ||

| SPN-1500 | 1500 |

|

70.50 | DN150 | DN80 | ||

| SPN-2000 | 2000 |

|

94.00 | DN150 | DN80 | ||

| SPN-2500 | 2500 |

|

117.50 | DN150 | DN100 | ||

FAQ:

Previous :

High Purified Liquid Nitrogen Generator with Superior QualityNext :

Skid-Mounted Industry Nitrogen GeneratorIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

10hp to 175hp Permanent Magnet Frequency Conversion Energy Saving Screw Air Compressor Read More

7.5Kw To 250 Kw Electric Direct Drive Rotary Screw Air Compressor Read More

11kW 15HP 16bar Combined Rotary Screw Air Compressor with Dryer, Air Tank for Laser Cutting Machines Use Read More

Silent Aircompressors Oilless Oil Free Belt Driven Scroll Air Compressor for Sale Read More

185CFM Diesel Portable Mining Screw Air Compressor Read More

© Copyright: 2026 Aircompsupplier All Rights Reserved.

IPv6 network supported

Friendly Links :

Solar Pile Driver