Pressure Swing Adsorption (PSA) is a new type of gas adsorption and separation technology. It has the following advantages:

1. Low cost: The advanced PSA process is a simple nitrogen production method. Nitrogen is generated within a few minutes after starting up, and the energy consumption is low. The cost of nitrogen is far lower than cryogenic air separation nitrogen production and liquid nitrogen on the market.3. Nitrogen purity is stable: it is completely monitored and displayed by the instrument to ensure the required nitrogen purity, and the instruments are integrated into the control box, which is convenient and simple.

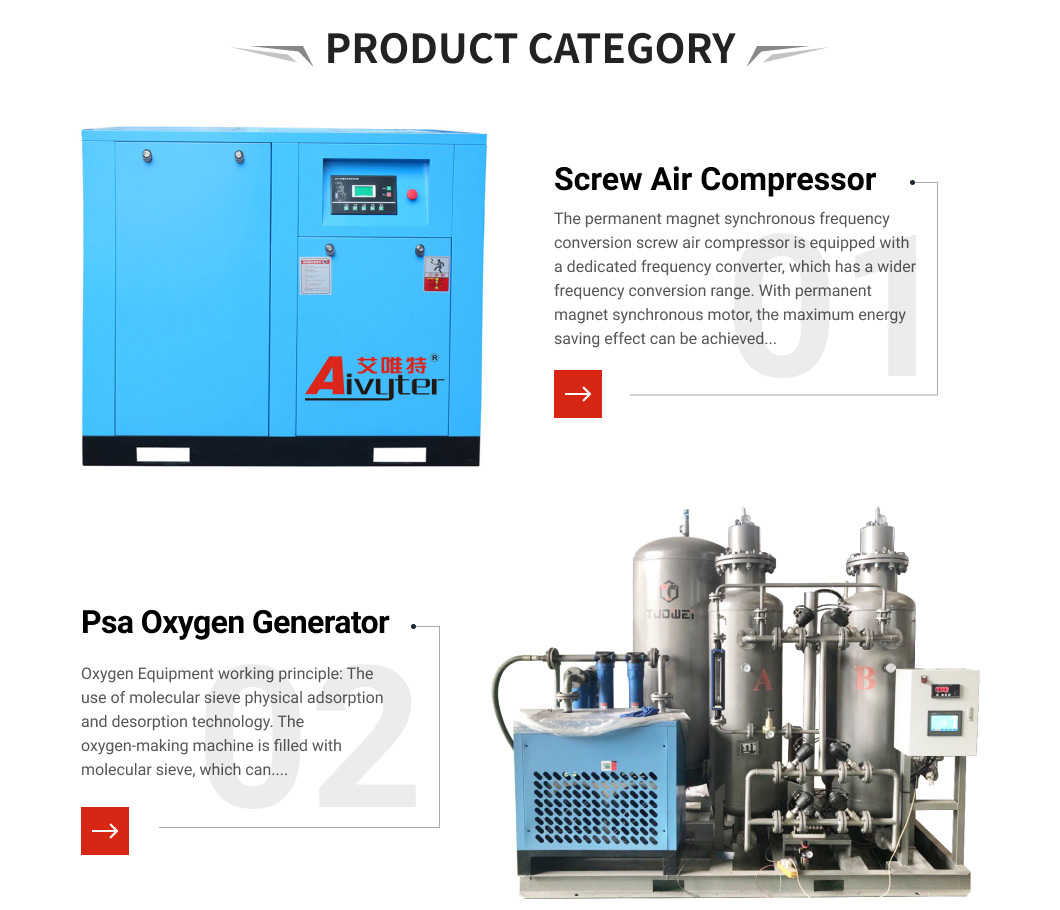

Equipment installation diagram

Δ Advanced inequality pressure equalization process improves the utilization of carbon molecular sieve and directly reduces compressed air consumption

Δ Advanced internal structure, air flow deceleration, uniform distribution, reduce the impact force on the molecular sieve, and improve the service life of the molecular sieve

Δ We cooperate with well-known molecular sieve manufacturers at home and abroad, and can choose the most energy-saving and efficient ratio according to actual working conditions.

Δ Reliable air source treatment accessories ensure the stable operation and service life of the equipment.

Δ Adopting the blizzard filling method, the molecular sieve is filled more evenly and densely, the friction coefficient is reduced to the minimum, and the whole machine is improved

Reliability of long-term operation.

Δ It adopts Siemens PLC programmable controller for automatic control, one-key start without special personnel operation, and can be reserved for computer, mobile phone, etc.

Remote device connection, real-time observation of operation.

Δ The valve is the key to the stable operation of the equipment, with fast opening and closing speed, low energy consumption, simple structure, good sealing performance, installation and maintenance

Convenient and long service life.

Δ Using a special spring compression device, when the molecular sieve in the adsorption tower decreases, it will automatically compensate to eliminate the problem of molecular sieve powdering.

Extended service life.

Δ Automatic emptying of unqualified nitrogen/manual emptying (optional)

Δ The original components of famous brands at home and abroad are selected to ensure the operation of the equipment and the quality of nitrogen.

When you send us inquiry, please kindly tell us the below technical information.

1) Flow rate:__Nm3/h

2) Purity:_%

3) Discharge pressure:_Bar

4) Voltages and Frequency:__V/PH/HZ

5) Application or use for which industry.

Previous :

Nitrogen Generator Cost Used For Photovoltaic IndustryNext :

Nitrogen Generator Machine for FoodIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

10hp to 175hp Permanent Magnet Frequency Conversion Energy Saving Screw Air Compressor Read More

7.5Kw To 250 Kw Electric Direct Drive Rotary Screw Air Compressor Read More

11kW 15HP 16bar Combined Rotary Screw Air Compressor with Dryer, Air Tank for Laser Cutting Machines Use Read More

Silent Aircompressors Oilless Oil Free Belt Driven Scroll Air Compressor for Sale Read More

185CFM Diesel Portable Mining Screw Air Compressor Read More

© Copyright: 2026 Aircompsupplier All Rights Reserved.

IPv6 network supported

Friendly Links :

Solar Pile Driver