Brand:

AivyterItem No.:

SGM 22Payment:

L/C , T/T , D/P , FOB,CIFProduct origin:

chinaShipping port:

shanghaiLead Time:

7~30 DayPower::

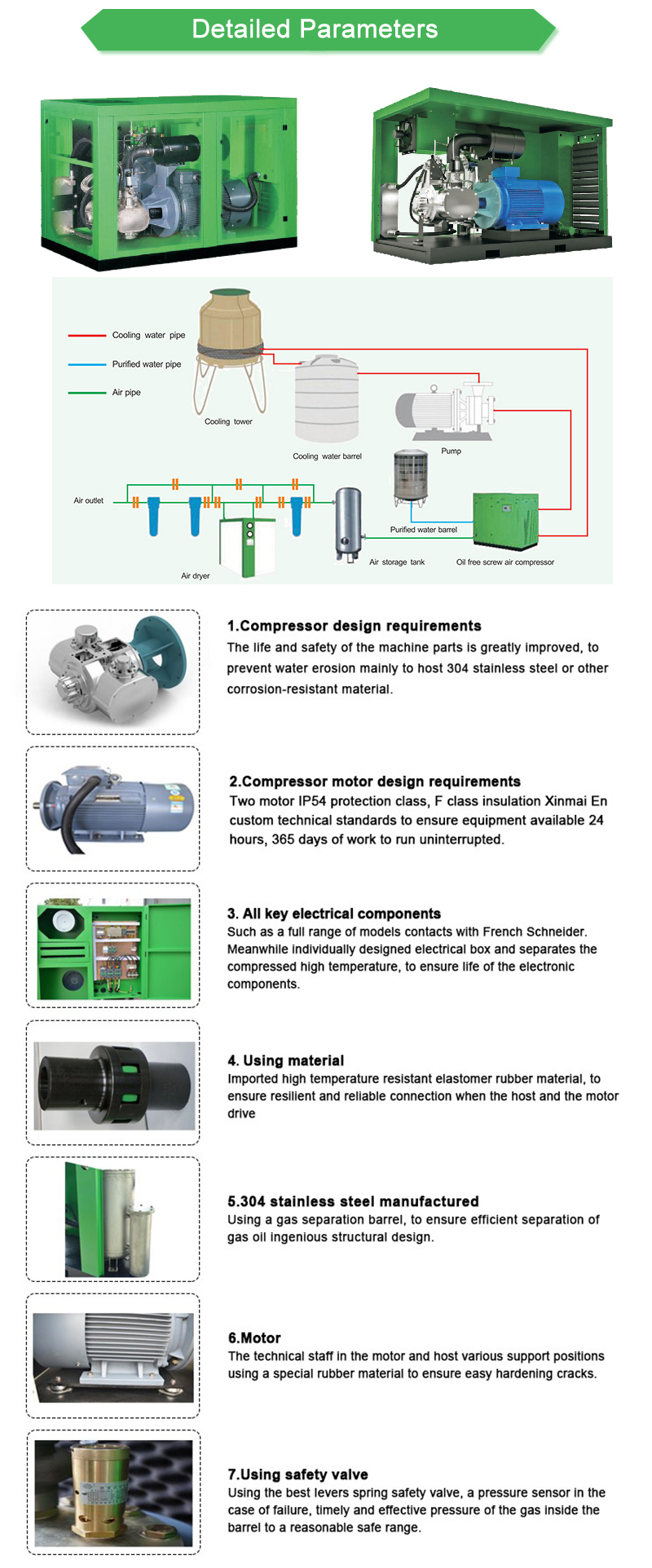

oil free compressorEnergy Saving Water Lubrication Injected Oil Free Rotary Screw Air Compressor

Company Information:

If you want to know our company information, please click Thank you.

FAQ

Q1: What is the rotor speed for the air end?

A1: 2980rmp.

Q2: What's your lead time?

A2: usually, 5-7 days. (OEM orders: 15days)

Q3: Can you offer water cooled air compressor?

A3: Yes, we can (normally, air cooled type).

Q4: What's the payment term?

A4: T/T, L/C, Western Union, etc. Also we could accept USD, RMB, and other currency.

Q5: Do you accept customized voltage?

A5: Yes. 380V/50Hz/3ph, 380V/60Hz/3ph, 220V/50Hz/3ph, 220V/60Hz/3ph, 440V/50Hz/3ph, 440V/60Hz/3ph, or as per your requests.

Q6: What is your warranty for air compressor?

A6: One year for the whole air compressor(not including the consumption spare parts) and technical supports can be provided according to your needs.

Q7: Can you accept OEM orders?

A7: Yes, OEM orders are warmly welcome.

Q8: How about your customer service and after-sales service?

A8: 24hrs on-line support, 48hrs problem solved promise.

Q9: Do you have spare parts in stock?

A9: Yes, we do.

Q10: What kind of initial lubrication oil you used in air compressor?

A10: TOTAL 46# mineral oil.

Previous :

37kW 50Hp Water Lubrication Oil Free Rotary Screw Air Compressor For Oxygen GeneratorNext :

Variable Frequency Oil Free Screw Air CompressorIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

10hp to 175hp Permanent Magnet Frequency Conversion Energy Saving Screw Air Compressor Read More

7.5Kw To 250 Kw Electric Direct Drive Rotary Screw Air Compressor Read More

11kW 15HP 16bar Combined Rotary Screw Air Compressor with Dryer, Air Tank for Laser Cutting Machines Use Read More

Silent Aircompressors Oilless Oil Free Belt Driven Scroll Air Compressor for Sale Read More

185CFM Diesel Portable Mining Screw Air Compressor Read More

© Copyright: 2026 Aircompsupplier All Rights Reserved.

IPv6 network supported

Friendly Links :

Solar Pile Driver