PSA oxygen generator can be used in hospitals, oxygen bottle washing, electric furnace steelmaking, wastewater treatment, non-ferrous metal smelting, petrochemical industry, aquaculture and other industries

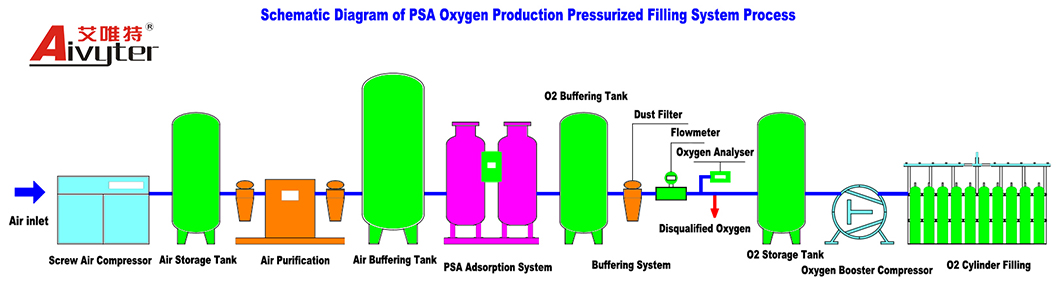

PSA Oxygen Generator Oxigen Generator for O2 Cylinder Filling and Hospital flow chart

The company has 10 years of experience, and we can help you configure the entire process of using the oxygen concentrator. Welcome to consult us

1. Specification of PSA oxygen generator

Model

O2 flow

O2 purity

Air consumption

Dimensions(mm)

m3/h

%

≥ m3/min

L*W*H

SPO93-5

5

93±2

1.08

2500×900×1900

SPO93-10

10

2.17

2500×1300×2100

SPO93-20

20

4.33

3000×1600×2200

SPO93-30

30

6.5

3400×2000×2450

SPO93-40

40

8.7

SPO93-50

50

10.83

SPO93-60

60

13

SPO93-70

70

15.17

SPO93-80

80

17.33

SPO93-90

90

19.5

SPO93-100

100

21.7

SPO93-120

120

26

SPO93-150

150

32.5

Custom size

SPO93-180

180

39

Custom size

SPO93-200

200

43.3

Custom size

2. PSA Oxygen generator Process Flow Brief Description

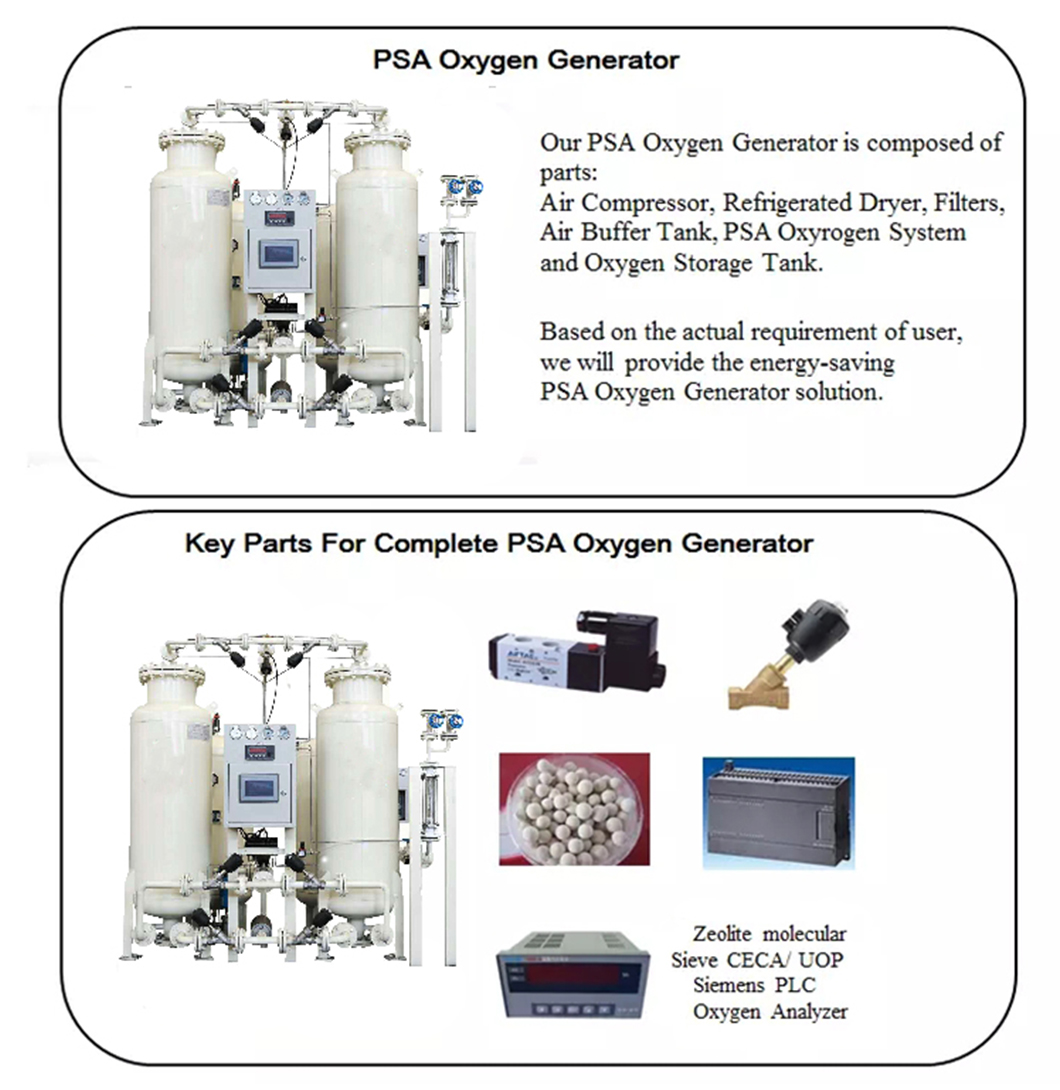

Oxygen Equipment working principle: The use of molecular sieve physical adsorption and desorption technology. The oxygen-making machine is filled with molecular sieve, which can adsorb nitrogen in the air when it is pressurized. The remaining non-absorbed oxygen is collected and purified to become high-purity oxygen. When the molecular sieve is decompressed, the adsorbed nitrogen is discharged back into the ambient air, and when the next pressure is applied, the nitrogen can be adsorbed and oxygen can be produced. The medical oxygen-producing equipment adopts the world advanced PSA (pressure swing adsorption) air separation and oxygen-producing technology, which realizes the separation of oxygen and nitrogen based on the difference of the adsorption ability of the adsorbent (zeolite molecular sieve) to the oxygen and nitrogen in the air. When the air enters the bed which contains the adsorbent, the nitrogen adsorption ability is strong, but the oxygen is not adsorbed, thus may obtain the high density oxygen at the adsorption bed outlet. Because the adsorbents have the characteristic that the amount of adsorbents changes with the pressure, the adsorption and desorption can be carried out alternately by changing the pressure.

3.Oxygen Generator Technical Features

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

10hp to 175hp Permanent Magnet Frequency Conversion Energy Saving Screw Air Compressor Read More

7.5Kw To 250 Kw Electric Direct Drive Rotary Screw Air Compressor Read More

11kW 15HP 16bar Combined Rotary Screw Air Compressor with Dryer, Air Tank for Laser Cutting Machines Use Read More

Silent Aircompressors Oilless Oil Free Belt Driven Scroll Air Compressor for Sale Read More

185CFM Diesel Portable Mining Screw Air Compressor Read More

© Copyright: 2026 Aircompsupplier All Rights Reserved.

IPv6 network supported

Friendly Links :

Solar Pile Driver