Item No.:

SPO93-50Product origin:

chinaShipping port:

hangzhouLead Time:

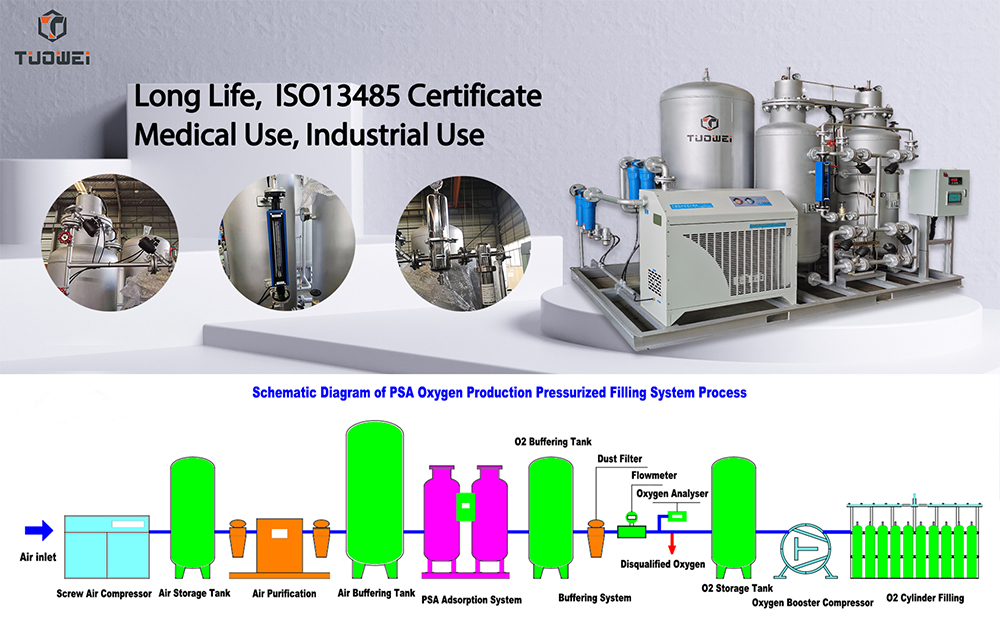

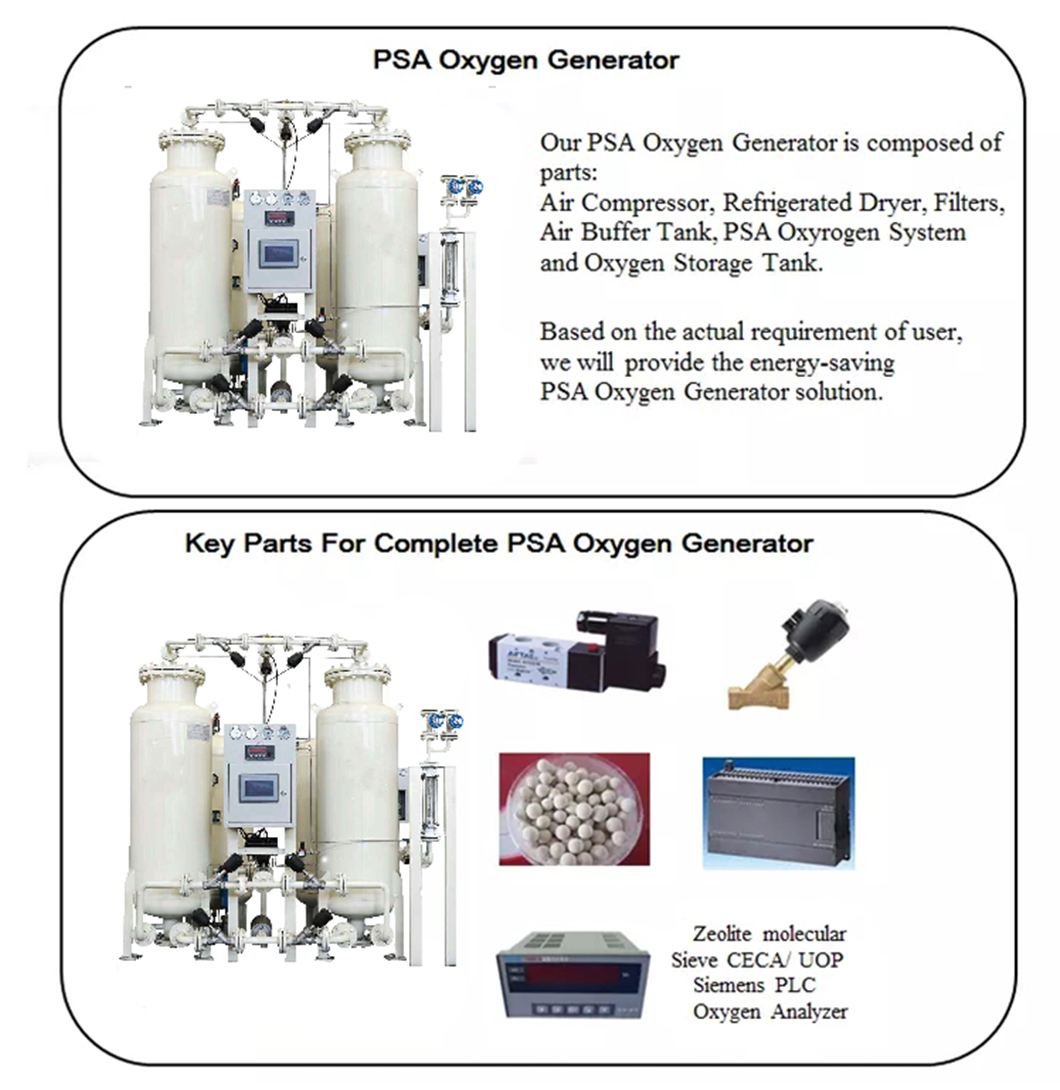

7~30 DayThe PSA oxygen generator is an automated equipment that is based on zeolite adsorbents and uses the principles of pressure adsorption, desorption, and decompression to adsorb and release nitrogen from the air to separate oxygen. Suitable for hospitals, oxygen cylinder flushing, etc.

Oxygen Generator System Features

1. High Oxygen Production and Low Energy Consumption

2. Low maintenance costs, Simple operation and easy maintenance .

3. Full Aotomation

4. Zeolite Molecular Sieves Life

5. Fast start-up

The device has compact structure, small floor area, skid-mounted structure and convenient installation.

Simple operation, fast start-up speed,15-30 minutesSimple operation, fast start-up speed,15-30 minutes can provide qualified oxygen;

Fully automatic operation of equipment, the wholeFully automatic operation of equipment, the whole process can achieve unattended;

Effective molecular sieve filing, tighter, more solid, longer service life;

Pressure, purity and flow are stable and adjustable to meet the different needs of customers.

Reasonable structure, advanced process, safety and stability, low energy consumption

| Model | O2 flow | O2 purity | Air consumption | Dimensions(mm) |

| m3/h | % | ≥ m3/min | L*W*H | |

| SPO93-5 | 5 | 93±2 | 1.08 | 2500×900×1900 |

| SPO93-10 | 10 | 2.17 | 2500×1300×2100 | |

| SPO93-20 | 20 | 4.33 | 3000×1600×2200 | |

| SPO93-30 | 30 | 6.5 | 3400×2000×2450 | |

| SPO93-40 | 40 | 8.7 |

Purification system:2500×1600×2400

Oxygen system:3000×1300×2400

|

|

| SPO93-50 | 50 | 10.83 |

Purification system:3000×1450×2400

Oxygen system:3100×1300×2400

|

|

| SPO93-60 | 60 | 13 |

Purification system:1250×1200×1800

Oxygen system:3100×1600×2400

|

|

| SPO93-70 | 70 | 15.17 |

Purification system:1250×1200×1800

Oxygen system:2600×2100×2400

|

|

| SPO93-80 | 80 | 17.33 |

Purification system:1250×1200×1800

Oxygen system:2600×2100×2480

|

|

| SPO93-90 | 90 | 19.5 |

Purification system:1300×1300×1800

Oxygen system:2800×2200×3200

|

|

| SPO93-100 | 100 | 21.7 |

Purification system:1300×1300×1800

Oxygen system:2800×2200×3200

|

|

| SPO93-120 | 120 | 26 |

Purification system:1650×1500×2100

Oxygen system:3200×2700×2400

|

|

| SPO93-150 | 150 | 32.5 | Custom size | |

| SPO93-180 | 180 | 39 | Custom size | |

| SPO93-200 | 200 | 43.3 | Custom size |

Q1: What's the system installation environment requirement?

A1:The system requires a dry ventilated environment.

Q2.What terms of payment you use?

A2:T/T, L/C, Western Union, etc. Also we could accept USD, RMB, and other currency

Q3.Do you offer customized services?

A3:Yes, We offer customized products according to different oxygen demand.

Q4. Before get a prompt quotation,which technical information is required?

A4:For hospital use:

A.Need to provide the Hospital oxygen servey, we would send the required information data table.

B.For other application:

1)O2 flow rate: _____Nm3/hr

2) O2 purity: _____%

3) O2 discharge pressure: _____Bar

4) Voltages and Frequency : ______V/PH/HZ

5) Application:

Q5.What about your after-sale services?

A5:We provide a variety of gas supply solutions according to customer requirements, and also provide users with repair and maintenance

Previous :

30 M3/H Medical Psa Oxygen Generator System Oxygen Plant Oxygen Generator for HospitalNext :

In Stock 50Nm3/h Medical Container PSA Oxygen Generator for Oxygen PlantIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

10hp to 175hp Permanent Magnet Frequency Conversion Energy Saving Screw Air Compressor Read More

7.5Kw To 250 Kw Electric Direct Drive Rotary Screw Air Compressor Read More

11kW 15HP 16bar Combined Rotary Screw Air Compressor with Dryer, Air Tank for Laser Cutting Machines Use Read More

Silent Aircompressors Oilless Oil Free Belt Driven Scroll Air Compressor for Sale Read More

185CFM Diesel Portable Mining Screw Air Compressor Read More

© Copyright: 2026 Aircompsupplier All Rights Reserved.

IPv6 network supported

Friendly Links :

Solar Pile Driver