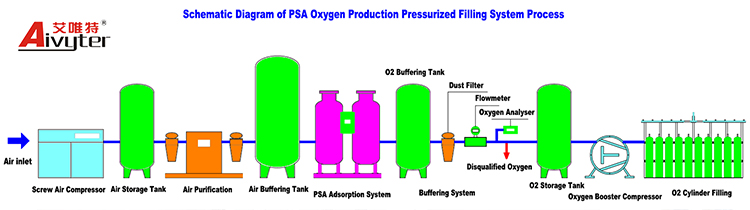

PSA Oxygen Generator based on the zeolite adsorbent by pressure adsorption, desorption antihypertensive principle of adsorbing and releasing nitrogen from air, thus separating oxygen automation equipment. Zeolite molecular sieve is processed by a special pore type treatment process. The spherical particle adsorbent with micropores on the surface and inside is white. Its pore type characteristics enable it to realize the kinetic separation of 02 and N2. The separation effect of zeolite molecular sieve on 02 and N2 is based on the small difference in the dynamic diameter of the two gases. N2 molecules have a faster diffusion rate in the micropores of zeolite molecular sieve, and O2 molecules have a slow diffusion rate. The diffusion of water and CO2 in compressed air is not much different from that of nitrogen. The final enrichment from the adsorption tower is oxygen molecules.

Medical Oxygen Generator PSA Oxygen Machine Working Principle Of Oxygen Generator

Oxygen Equipment working principle: The use of molecular sieve physical adsorption and desorption technology. The oxygen-making machine is filled with molecular sieve, which can adsorb nitrogen in the air when it is pressurized. The remaining non-absorbed oxygen is collected and purified to become high-purity oxygen. When the molecular sieve is decompressed, the adsorbed nitrogen is discharged back into the ambient air, and when the next pressure is applied, the nitrogen can be adsorbed and oxygen can be produced. The medical oxygen-producing equipment adopts the world advanced PSA (pressure swing adsorption) air separation and oxygen-producing technology, which realizes the separation of oxygen and nitrogen based on the difference of the adsorption ability of the adsorbent (zeolite molecular sieve) to the oxygen and nitrogen in the air. When the air enters the bed which contains the adsorbent, the nitrogen adsorption ability is strong, but the oxygen is not adsorbed, thus may obtain the high density oxygen at the adsorption bed outlet. Because the adsorbents have the characteristic that the amount of adsorbents changes with the pressure, the adsorption and desorption can be carried out alternately by changing the pressure.

Technical characteristics

1). Fully automatic

All systems are designed for unattended operation and automatic regulation of nitrogen demand.

2). Low space requirement

The design and instrumentation make the factory very compact and can be assembled on prefabricated slides in the factory.

3). Quick Start

The start-up time only takes 5 minutes to obtain the required oxygen purity, so these devices can be turned on and off according to changes in oxygen demand.

4). High reliability

The oxygen purity is constant, continuous and stable operation, very reliable, the available time of the factory is always better than 93%±2.

5). Molecular sieve life

The expected life of the molecular sieve is about 15 years, that is, the entire life of the nitrogen-making equipment, so there is no need for replacement costs.

6). Adjustable

By changing the flow rate, you can deliver oxygen with just the right purity.

Psa Oxygen Generator Technical Parameters

Model

O2 flow

O2 purity

Air consumption

Dimensions(mm)

m3/h

%

≥ m3/min

L*W*H

SPO93-5

5

93±2

1.08

2500×900×1900

SPO93-10

10

2.17

2500×1300×2100

SPO93-20

20

4.33

3000×1600×2200

SPO93-30

30

6.5

3400×2000×2450

SPO93-40

40

8.7

SPO93-50

50

10.83

SPO93-60

60

13

SPO93-70

70

15.17

SPO93-80

80

17.33

SPO93-90

90

19.5

SPO93-100

100

21.7

SPO93-120

120

26

SPO93-150

150

32.5

Custom size

SPO93-180

180

39

Custom size

SPO93-200

200

43.3

Custom size

FAQ:

Q1: What's the system installation environment requirement?

A1:The system requires a dry ventilated environment.

Q2.What terms of payment you use?

A2:T/T, L/C, Western Union, etc. Also we could accept USD, RMB, and other currency

Q3.Do you offer customized services?

A3:Yes, We offer customized products according to different oxygen demand.

Q4. Before get a prompt quotation,which technical information is required?

A4:For hospital use:

A.Need to provide the Hospital oxygen servey, we would send the required information data table.

B.For other application:

1)O2 flow rate: _____Nm3/hr

2) O2 purity: _____%

3) O2 discharge pressure: _____Bar

4) Voltages and Frequency : ______V/PH/HZ

5) Application:

Q5.What about your after-sale services?

A5:We provide a variety of gas supply solutions according to customer requirements, and also provide users with repair and maintenance

Previous :

Fast Delivery 60m3/h Psa Oxygen Generator For SaleNext :

PSA Oxygen Generator Oxygen Making Machine IndustrialIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

10hp to 175hp Permanent Magnet Frequency Conversion Energy Saving Screw Air Compressor Read More

7.5Kw To 250 Kw Electric Direct Drive Rotary Screw Air Compressor Read More

11kW 15HP 16bar Combined Rotary Screw Air Compressor with Dryer, Air Tank for Laser Cutting Machines Use Read More

Silent Aircompressors Oilless Oil Free Belt Driven Scroll Air Compressor for Sale Read More

185CFM Diesel Portable Mining Screw Air Compressor Read More

© Copyright: 2026 Aircompsupplier All Rights Reserved.

IPv6 network supported

Friendly Links :

Solar Pile Driver