Pressure swing adsorption oxygen production equipment it has the advantages of low equipment cost, small size, light weight, simple operation, convenient maintenance, low operating cost, fast on-site oxygen production, convenient switching, and pollution-free. It can be suitable for steel cutting, rich Oxygen-assisted combustion, hospital oxygen, etc. and cryogenic oxygen equipment high purity of oxygen, long service life of the equipment.

Pressure Swing Adsorption Oxygen Concentrator Oxygen Plant

Product Details:

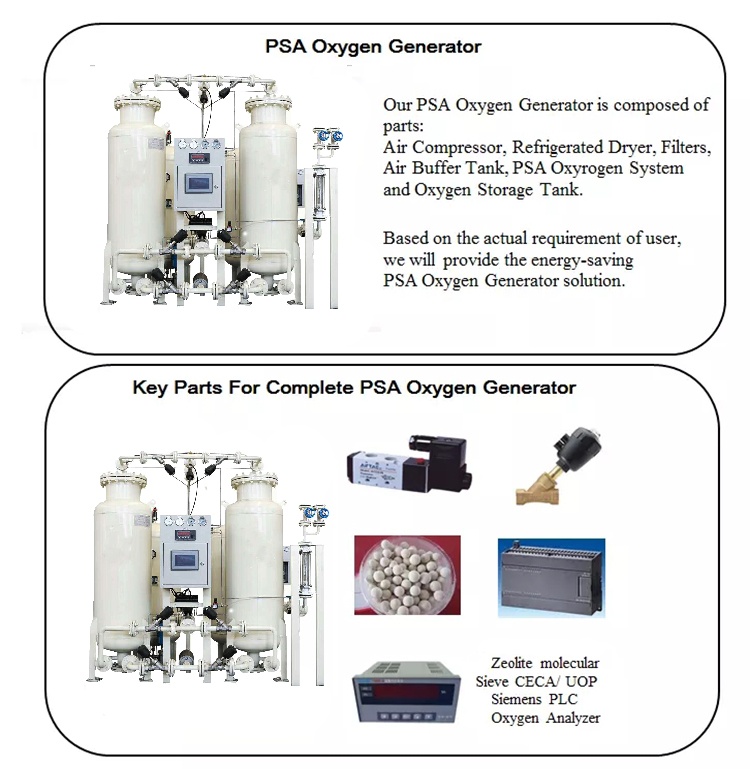

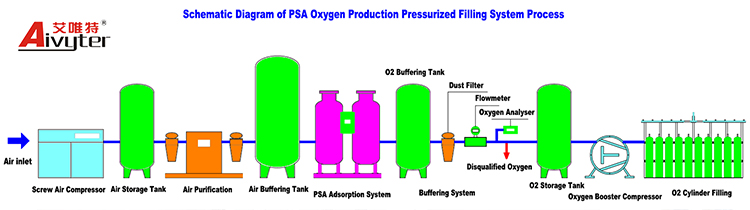

The working principle of oxygen production equipment: using molecular sieve physical adsorption and desorption technology. The oxygen generator is equipped with molecular sieves, which can adsorb nitrogen in the air when pressurized. The remaining unabsorbed oxygen is collected and purified into high purity oxygen.

1. The PSA oxygen production mechanism has a fast oxygen speed. The oxygen production can be started at any time, and it can be shut down at any time. The operation is flexible and flexible.

2. A high degree of automation can be achieved. The adsorption and separation process is controlled by PLC, and the administrator is on duty remotely.

3. The gas separation cost is low, and the main operating cost is power consumption.

4. The molecular sieve has a long service life. It can be used for 8-10 years through formal and professional filling and filtering treatment.

5. The equipment has a compact structure, a small area, and reduces additional infrastructure.

6. Gas purity and output can be adjusted appropriately, high efficiency, environmental protection and energy saving.

7. A set of system includes three components: air compression system, compressed air purification system, and adsorption separation system.

8. The advanced control system makes the operation simple and can effectively guarantee the stability of gas purity and flow rate.

Psa Oxygen Generator Technical Parameters

Model

O2 flow

O2 purity

Air consumption

Dimensions(mm)

m3/h

%

≥ m3/min

L*W*H

SPO93-5

5

93±2

1.08

2500×900×1900

SPO93-10

10

2.17

2500×1300×2100

SPO93-20

20

4.33

3000×1600×2200

SPO93-30

30

6.5

3400×2000×2450

SPO93-40

40

8.7

SPO93-50

50

10.83

SPO93-60

60

13

SPO93-70

70

15.17

SPO93-80

80

17.33

SPO93-90

90

19.5

SPO93-100

100

21.7

SPO93-120

120

26

SPO93-150

150

32.5

Custom size

SPO93-180

180

39

Custom size

SPO93-200

200

43.3

Custom size

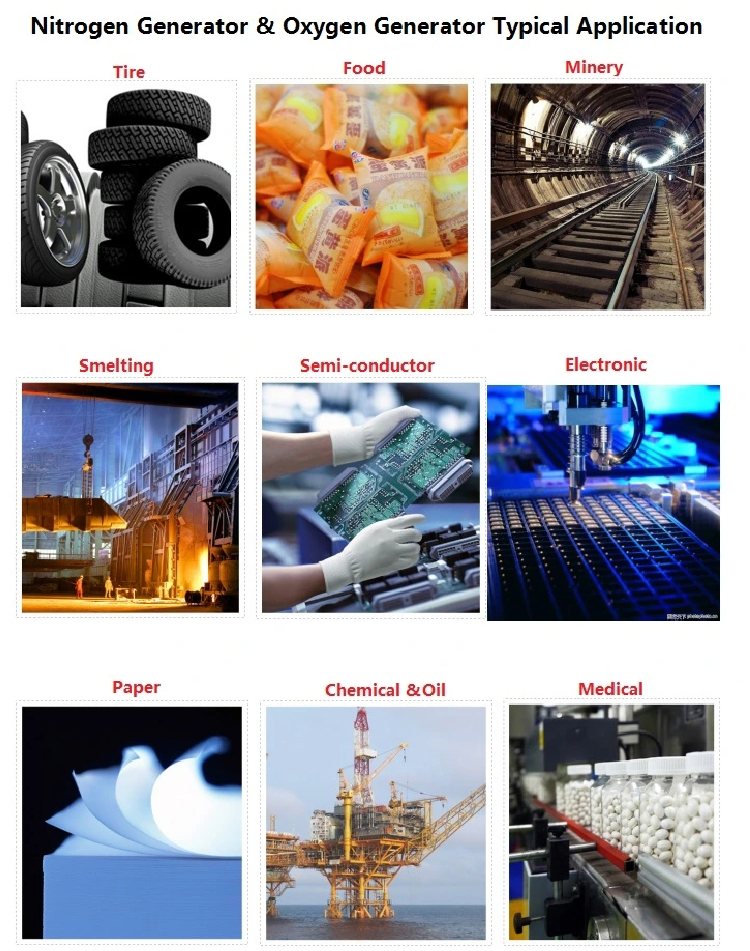

Application industry

FAQ:

Q1: What's the system installation environment requirement?

A1:The system requires a dry ventilated environment.

Q2.What terms of payment you use?

A2:T/T, L/C, Western Union, etc. Also we could accept USD, RMB, and other currency

Q3.Do you offer customized services?

A3:Yes, We offer customized products according to different oxygen demand.

Q4. Before get a prompt quotation,which technical information is required?

A4:For hospital use:

A.Need to provide the Hospital oxygen servey, we would send the required information data table.

B.For other application:

1)O2 flow rate: _____Nm3/hr

2) O2 purity: _____%

3) O2 discharge pressure: _____Bar

4) Voltages and Frequency : ______V/PH/HZ

5) Application:

Q5.What about your after-sale services?

A5:We provide a variety of gas supply solutions according to customer requirements, and also provide users with repair and maintenance

Previous :

PSA Oxygen Generator Oxygen Making Machine IndustrialNext :

Medical Oxygen Producing Machine Psa Oxygen Generator Oxygen PlantIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

10hp to 175hp Permanent Magnet Frequency Conversion Energy Saving Screw Air Compressor Read More

7.5Kw To 250 Kw Electric Direct Drive Rotary Screw Air Compressor Read More

11kW 15HP 16bar Combined Rotary Screw Air Compressor with Dryer, Air Tank for Laser Cutting Machines Use Read More

Silent Aircompressors Oilless Oil Free Belt Driven Scroll Air Compressor for Sale Read More

185CFM Diesel Portable Mining Screw Air Compressor Read More

© Copyright: 2026 Aircompsupplier All Rights Reserved.

IPv6 network supported

Friendly Links :

Solar Pile Driver