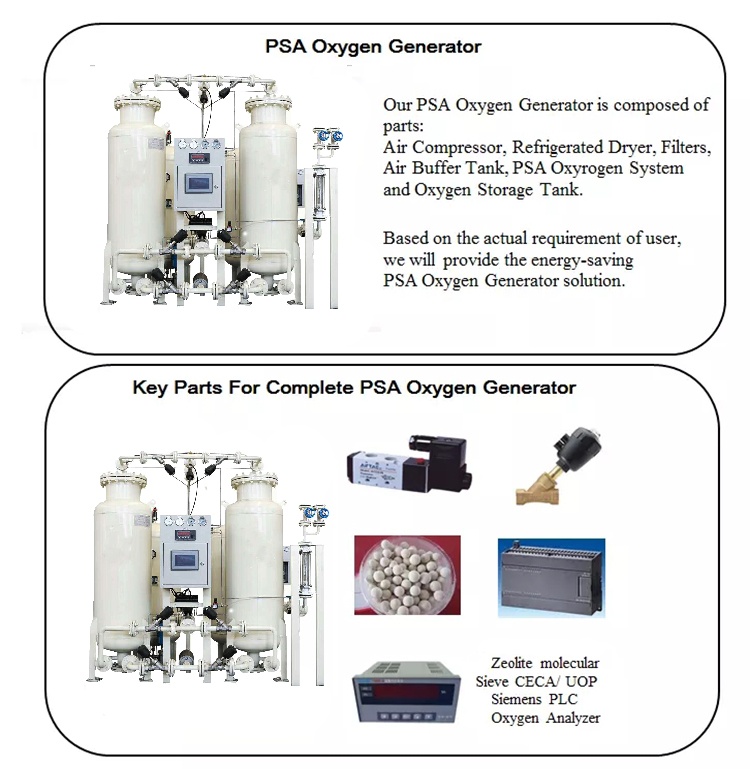

The psa oxygen generator is an automated equipment that separates oxygen by adsorbing and releasing nitrogen from the air through the principle of pressure adsorption, desorption, and pressure reduction based on zeolite adsorbents. The zeolite molecular sieve is processed by a special hole type treatment process. The spherical particle adsorbent with micropores on the surface and inside is white. Its pore type characteristics enable it to realize the kinetic separation of O2 and N2. The separation effect of zeolite molecular sieve on O2 and N2 is based on the small difference in the dynamic diameter of the two gases. The diffusion rate of N2 molecules in the micropores of the zeolite molecular sieve is faster, and the diffusion rate of O2 molecules is slower. The diffusion of water and CO2 in compressed air is not much different from the diffusion of nitrogen. The final enrichment of the adsorption tower is oxygen molecules.

Gas Generation Equipment 30m3/h Hospital Oxygen Generator Oxygen Plant Cost

1.Unique carbon molecular sieve protection measures extend the service life of carbon molecular sieve.

2.Compact molecular sieve to prevent molecular sieve from dusting,Extend the service life of the oxygen generator.

3. The equipment has the advantages of low energy consumption, low cost, strong adaptability, fast gas production and easy adjustment of purity.

4.Perfect process design and best use effect;

5.Modular design is designed to save land area.

The working principle of PSA oxygen production equipment: adopts molecular sieve physical adsorption and desorption technology. The oxygen generator is equipped with molecular sieves, which can adsorb nitrogen in the air when pressurized. The remaining unabsorbed oxygen is collected and purified into high purity oxygen. The medical oxygen production equipment adopts the world's advanced PSA (pressure swing adsorption) air separation oxygen production technology. According to the different adsorption capacity of the adsorbent (zeolite molecular sieve), the separation of oxygen and nitrogen can achieve high density at the outlet of the adsorbent bed oxygen.

| Model | O2 flow | O2 purity | Air consumption | Dimensions(mm) |

| m3/h | % | ≥ m3/min | L*W*H | |

| SPO93-5 | 5 | 93±2% | 1.08 | 2500×900×1900 |

| SPO93-10 | 10 | 2.17 | 2500×1300×2100 | |

| SPO93-20 | 20 | 4.33 | 3000×1600×2200 | |

| SPO93-30 | 30 | 6.5 | 3400×2000×2450 | |

| SPO93-40 | 40 | 8.7 |

Purification system:2500×1600×2400

Oxygen system:3000×1300×2400

|

|

| SPO93-50 | 50 | 10.83 |

Purification system:3000×1450×2400

Oxygen system:3100×1300×2400

|

|

| SPO93-60 | 60 | 13 |

Purification system:1250×1200×1800

Oxygen system:3100×1600×2400

|

|

| SPO93-70 | 70 | 15.17 |

Purification system:1250×1200×1800

Oxygen system:2600×2100×2400

|

|

| SPO93-80 | 80 | 17.33 |

Purification system:1250×1200×1800

Oxygen system:2600×2100×2480

|

|

| SPO93-90 | 90 | 19.5 |

Purification system:1300×1300×1800

Oxygen system:2800×2200×3200

|

|

| SPO93-100 | 100 | 21.7 |

Purification system:1300×1300×1800

Oxygen system:2800×2200×3200

|

|

| SPO93-120 | 120 | 26 |

Purification system:1650×1500×2100

Oxygen system:3200×2700×2400

|

|

| SPO93-150 | 150 | 32.5 | Custom size | |

| SPO93-180 | 180 | 39 | Custom size | |

| SPO93-200 | 200 | 43.3 | Custom size |

Q1: What's the system installation environment requirement?

A1:The system requires a dry ventilated environment.

Q2.What terms of payment you use?

A2:T/T, L/C, Western Union, etc. Also we could accept USD, RMB, and other currency

Q3.Do you offer customized services?

A3:Yes, We offer customized products according to different oxygen demand.

Q4. Before get a prompt quotation,which technical information is required?

A4:For hospital use:

A.Need to provide the Hospital oxygen servey, we would send the required information data table.

B.For other application:

1)O2 flow rate: _____Nm3/hr

2) O2 purity: _____%

3) O2 discharge pressure: _____Bar

4) Voltages and Frequency : ______V/PH/HZ

5) Application:

Q5.What about your after-sale services?

A5:We provide a variety of gas supply solutions according to customer requirements, and also provide users with repair and maintenance

Previous :

In Stock 20m3/h Medical Psa Oxigen Generator for Hospital Oxygen Gas PlantNext :

30 M3/H Medical Psa Oxygen Generator System Oxygen Plant Oxygen Generator for HospitalIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

10hp to 175hp Permanent Magnet Frequency Conversion Energy Saving Screw Air Compressor Read More

7.5Kw To 250 Kw Electric Direct Drive Rotary Screw Air Compressor Read More

11kW 15HP 16bar Combined Rotary Screw Air Compressor with Dryer, Air Tank for Laser Cutting Machines Use Read More

Silent Aircompressors Oilless Oil Free Belt Driven Scroll Air Compressor for Sale Read More

185CFM Diesel Portable Mining Screw Air Compressor Read More

© Copyright: 2026 Aircompsupplier All Rights Reserved.

IPv6 network supported

Friendly Links :

Solar Pile Driver