PSA oxygen generator is an automated equipment that separates oxygen by adsorbing and releasing nitrogen from the air through the principle of pressure adsorption, desorption, and pressure reduction based on zeolite adsorbents. The zeolite molecular sieve is processed by a special hole type treatment process. The spherical particle adsorbent with micropores on the surface and inside is white. Its pore type characteristics enable it to realize the kinetic separation of O2 and N2. The separation effect of zeolite molecular sieve on O2 and N2 is based on the small difference in the dynamic diameter of the two gases. The diffusion rate of N2 molecules in the micropores of the zeolite molecular sieve is faster, and the diffusion rate of O2 molecules is slower. The diffusion of water and CO2 in compressed air is not much different from the diffusion of nitrogen. The final enrichment of the adsorption tower is oxygen molecules.Suitable for hospitals, oxygen bottle flushing, etc.

In Stock 20m3/h Medical Psa Oxigen Generator for Hospital Oxygen Gas Plant

Product Details:

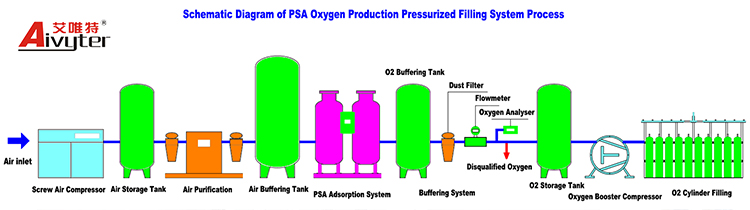

The PSA oxygen generator is an air separation device based on molecular sieve that selectively adsorbs nitrogen from the air. It can continuously generate gaseous oxygen with a purity of 90-96% at room temperature. The adsorbed nitrogen can be desorbed by reducing the adsorption bed to cause cyclic adsorption. -Desorption operation.

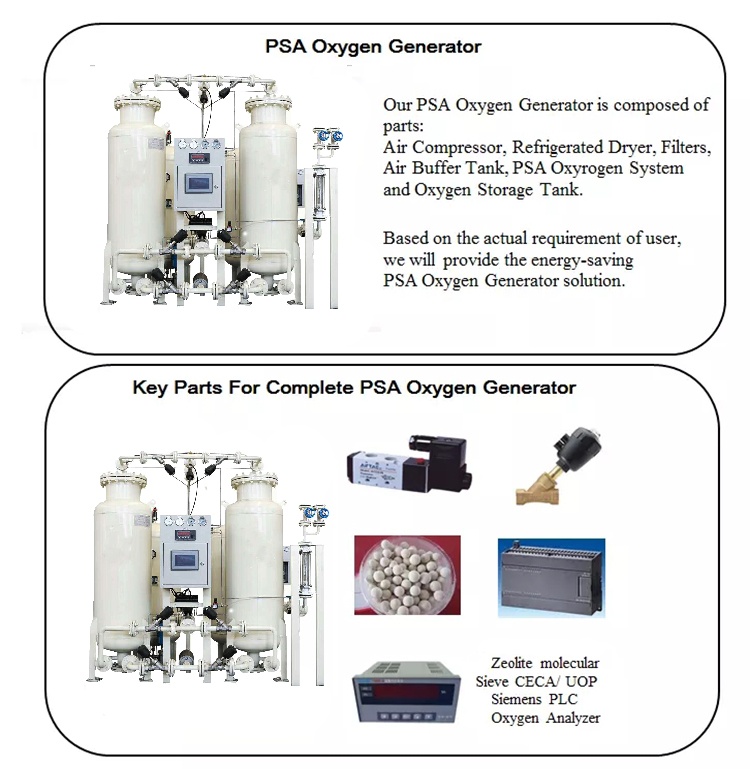

The working principle of PSA oxygen production equipment: using molecular sieve physical adsorption and desorption technology. The oxygen generator is equipped with molecular sieves, which can adsorb nitrogen in the air when pressurized. The remaining unabsorbed oxygen is collected and purified into high purity oxygen. The medical oxygen production equipment adopts the world's advanced PSA (pressure swing adsorption) air separation oxygen production technology, and realizes the separation of oxygen and nitrogen according to the adsorption capacity of the adsorbent (zeolite molecular sieve). The PSA oxygen production system consists of a compressed air system, a compressed air purification system, a PSA oxygen production system and an oxygen storage system.

Psa Oxygen Generator Technical Parameters

| Model | O2 flow | O2 purity | Air consumption | Dimensions(mm) |

| m3/h | % | ≥ m3/min | L*W*H | |

| SPO93-5 | 5 | 93±2 | 1.08 | 2500×900×1900 |

| SPO93-10 | 10 | 2.17 | 2500×1300×2100 | |

| SPO93-20 | 20 | 4.33 | 3000×1600×2200 | |

| SPO93-30 | 30 | 6.5 | 3400×2000×2450 | |

| SPO93-40 | 40 | 8.7 |

Purification system:2500×1600×2400

Oxygen system:3000×1300×2400

|

|

| SPO93-50 | 50 | 10.83 |

Purification system:3000×1450×2400

Oxygen system:3100×1300×2400

|

|

| SPO93-60 | 60 | 13 |

Purification system:1250×1200×1800

Oxygen system:3100×1600×2400

|

|

| SPO93-70 | 70 | 15.17 |

Purification system:1250×1200×1800

Oxygen system:2600×2100×2400

|

|

| SPO93-80 | 80 | 17.33 |

Purification system:1250×1200×1800

Oxygen system:2600×2100×2480

|

|

| SPO93-90 | 90 | 19.5 |

Purification system:1300×1300×1800

Oxygen system:2800×2200×3200

|

|

| SPO93-100 | 100 | 21.7 |

Purification system:1300×1300×1800

Oxygen system:2800×2200×3200

|

|

| SPO93-120 | 120 | 26 |

Purification system:1650×1500×2100

Oxygen system:3200×2700×2400

|

|

| SPO93-150 | 150 | 32.5 | Custom size | |

| SPO93-180 | 180 | 39 | Custom size | |

| SPO93-200 | 200 | 43.3 | Custom size |

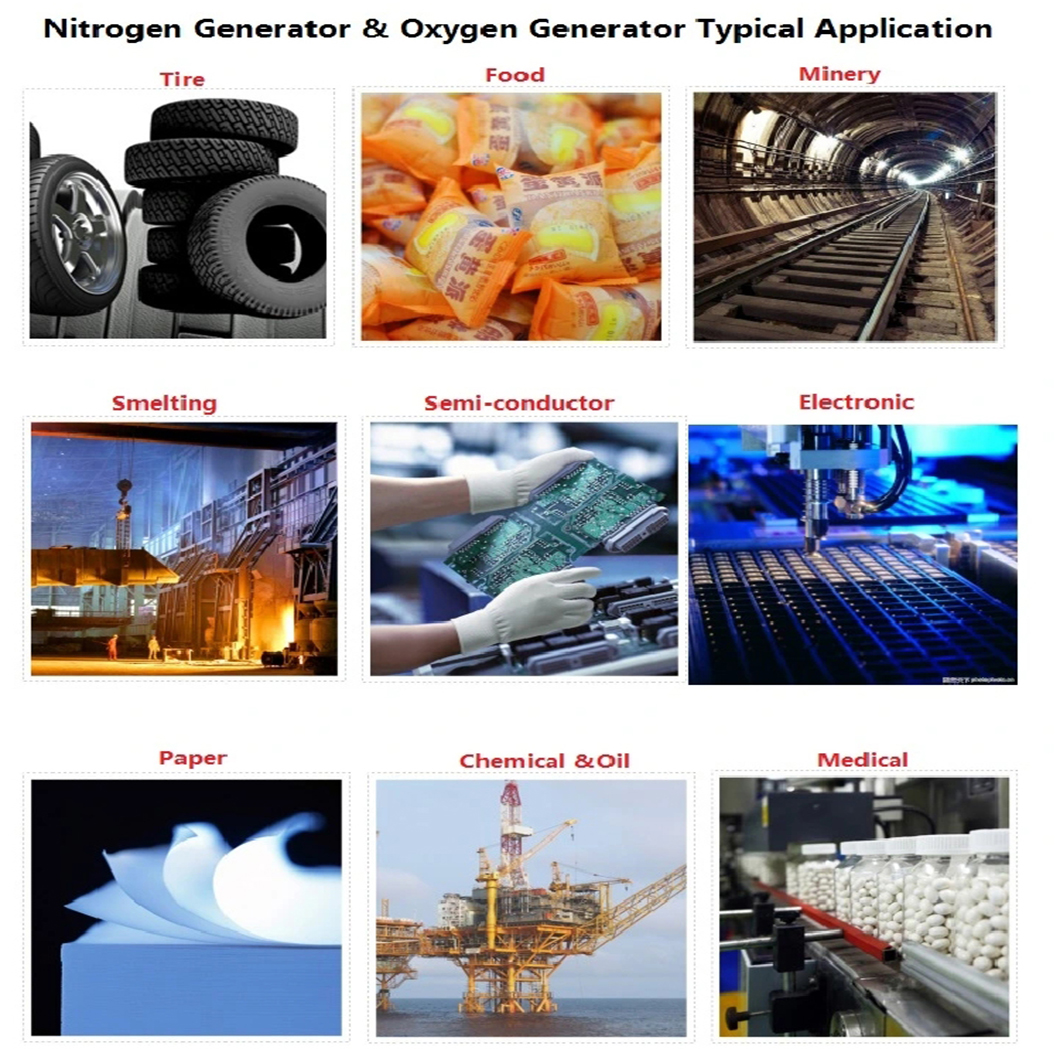

Application industry

Company Profile

Aircompsupplier Mechanical & Electrical Equipment Co., Ltd, established in 2010, is a professional enterprise engaged in the research, development, sale and service of air compressor, screw air compressor, air dryer, filters, oxygen generator, nitrogen generator and wet spray manipulator.

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction by supplying air and gas. Aircompsupplier company not only has its own import and export right and stable distributors worldwide, but also has a team of professional after sales and service. In addition, we have obtained CE, TUV, SGS, ISO certificates.

After long-term development, our company has established two wellknown brands: Aircompsupplier and Aircompsupplier.

In domestic market, our Aircompsupplier brand of screw air compressors and wet spray manipulators are well-known in tunnel industry. with cooperation of China Railway Bureau Group Co, Ltd, and also formed a long-term strategic partnership with China Railwaywith (the first) Bureau Group Co, Ltd to China Railway(the tenth) Bureau Group Co., Ltd.

Selling well in all cities and provinces around China, our products are also exported to clients in many countries and regions, such as, Russia, Thailand, Vietnam, Indonesia, South Africa, Tunisia, Saudi Arabia, Uzbekistan, Danmark, Poland, Mexico, Chile, Peru, India, Pakistan, Malaysia, etc.

Our products gain wide praises at home and abroad. We also welcome OEM, ODM orders. As a supplier, Aircompsupplier has its own factory, covers an area of 10,000 square meters, with 500 sets output of screw air compressors and 100 sets of oxygen generators per month, with 5 engineers in technical dept, and more than 100 workers.

Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can email or phone us about your sourcing requirements. We warmly welcome customers all over the world to establish cooperation and create a bright future with us together.

FAQ:

Q1: What's the system installation environment requirement?

A1:The system requires a dry ventilated environment.

Q2.What terms of payment you use?

A2:T/T, L/C, Western Union, etc. Also we could accept USD, RMB, and other currency

Q3.Do you offer customized services?

A3:Yes, We offer customized products according to different oxygen demand.

Q4. Before get a prompt quotation,which technical information is required?

A4:For hospital use:

A.Need to provide the Hospital oxygen servey, we would send the required information data table.

B.For other application:

1)O2 flow rate: _____Nm3/hr

2) O2 purity: _____%

3) O2 discharge pressure: _____Bar

4) Voltages and Frequency : ______V/PH/HZ

5) Application:

Q5.What about your after-sale services?

A5:We provide a variety of gas supply solutions according to customer requirements, and also provide users with repair and maintenance

Previous :

In Stock 20m3/h Medical PSA Oxygen Generator For Oxygen Filling MachineNext :

Gas Generation Equipment 30m3/h Hospital Oxygen Generator Oxygen Plant CostIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

10hp to 175hp Permanent Magnet Frequency Conversion Energy Saving Screw Air Compressor Read More

7.5Kw To 250 Kw Electric Direct Drive Rotary Screw Air Compressor Read More

11kW 15HP 16bar Combined Rotary Screw Air Compressor with Dryer, Air Tank for Laser Cutting Machines Use Read More

Silent Aircompressors Oilless Oil Free Belt Driven Scroll Air Compressor for Sale Read More

185CFM Diesel Portable Mining Screw Air Compressor Read More

© Copyright: 2026 Aircompsupplier All Rights Reserved.

IPv6 network supported

Friendly Links :

Solar Pile Driver