The oil injected screw air compressor waste heat energy-saving water heater is an energy-saving hot water equipment that uses the high-temperature oil and gas heat of the air compressor to fully utilize the heat energy through the heat energy exchanger. It is controlled by heat exchange and power saving. Collect the heat energy generated by the air compressor during operation. While collecting the heat energy of the air compressor, it also effectively improves the operating conditions of the air compressor. It is an energy-saving equipment with high-efficiency waste heat recovery and utilization, no oil burning, no power consumption, energy saving, environmental protection and zero-cost operation.

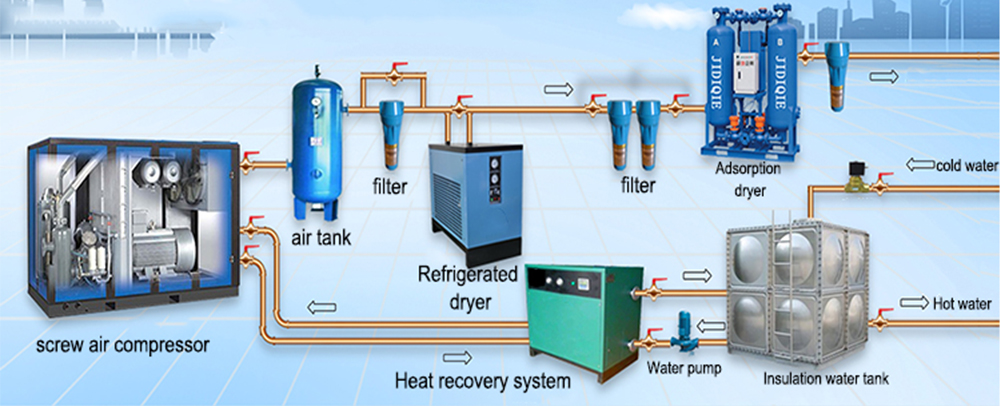

Working Principle:

The air compressor waste heat energy-saving hot water unit uses the high-temperature oil and gas heat generated during the operation of the air compressor, and transfers the heat energy to the room temperature water through the heat exchanger to realize the collection and utilization of heat energy. As shown in the figure, the motor drives the screw to rotate and the air is sucked in through the filter. The high-pressure air is formed in the screw compressor and mixed with the circulating oil to form a high-temperature oil and gas mixture, which enters the oil and gas separator. The oil and gas mixture is divided into high-temperature oil and high-pressure gas. After the oil and gas separator is separated, it is condensed into a liquid state and then radiated by the cooler. The filter is filtered and returned to the compressor to complete a cycle process. In the energy-saving water heater unit, the heat exchanger fully recovers the high-temperature heat generated during the operation of the air compressor, and at the same time, it effectively reduces the operating temperature of the air compressor and improves the effective operation of the air compressor to increase the gas production.

Product Parameter:

Product number

Suitable air compressor power

Waste heat utilization

Tubing diameter

Outlet diameter

Trachea diameter

Outlet temperature

Hot water production

Applicable number

GD30A

22/30

17.6

DN15

DN25

DN40

55-85

0.35-0.2

300-350

GD30R

22/30

35.2

DN15

DN25

DN40

55-85

0.698-0.4

600-700

GD30RA

22/30

25.25

DN15

DN25

DN40

55-85

0.4-0.23

350-400

GD50A

37/50

29.6

DN15

DN25

DN50

55-85

0.58-0.33

480-550

GD50R

37/50

59.2

DN15

DN25

DN50

55-85

1.166-0.66

950-1000

GD50RA

37/50

42.9

DN15

DN25

DN50

55-85

0.68-0.38

580-600

GD60A

45/60

36

DN20

DN25

DN50

55-85

0.696-0.39

560-670

GD60R

45/60

72

DN20

DN25

DN50

55-85

1.39-0.79

1100-1350

GD60RA

45/60

52.2

DN20

DN25

DN50

55-85

0.8-0.45

640-790

GD75A

55/75

44

DN20

DN32

DN65

55-85

0.87-0.5

700-830

GD75R

55/75

88

DN20

DN32

DN65

55-85

1.74-1

1400-1670

GD75RA

55/75

51

DN20

DN32

DN65

55-85

1.01-0.58

810-970

GD100A

75/100

60

DN25

DN32

DN65

55-85

1.16-0.66

930-1100

GD100R

75/100

120

DN25

DN32

DN65

55-85

2.32-1.32

1860-2200

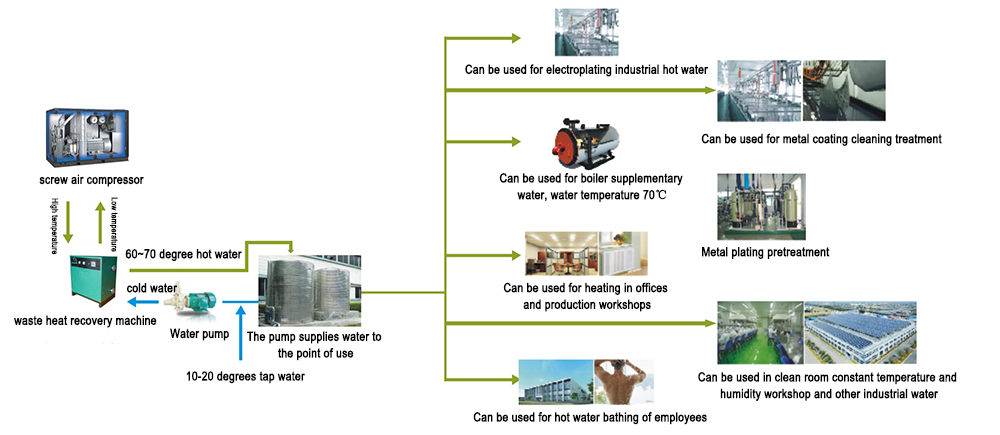

Application:

Company Information:

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

10hp to 175hp Permanent Magnet Frequency Conversion Energy Saving Screw Air Compressor Read More

7.5Kw To 250 Kw Electric Direct Drive Rotary Screw Air Compressor Read More

11kW 15HP 16bar Combined Rotary Screw Air Compressor with Dryer, Air Tank for Laser Cutting Machines Use Read More

Silent Aircompressors Oilless Oil Free Belt Driven Scroll Air Compressor for Sale Read More

185CFM Diesel Portable Mining Screw Air Compressor Read More

© Copyright: 2026 Aircompsupplier All Rights Reserved.

IPv6 network supported

Friendly Links :

Solar Pile Driver