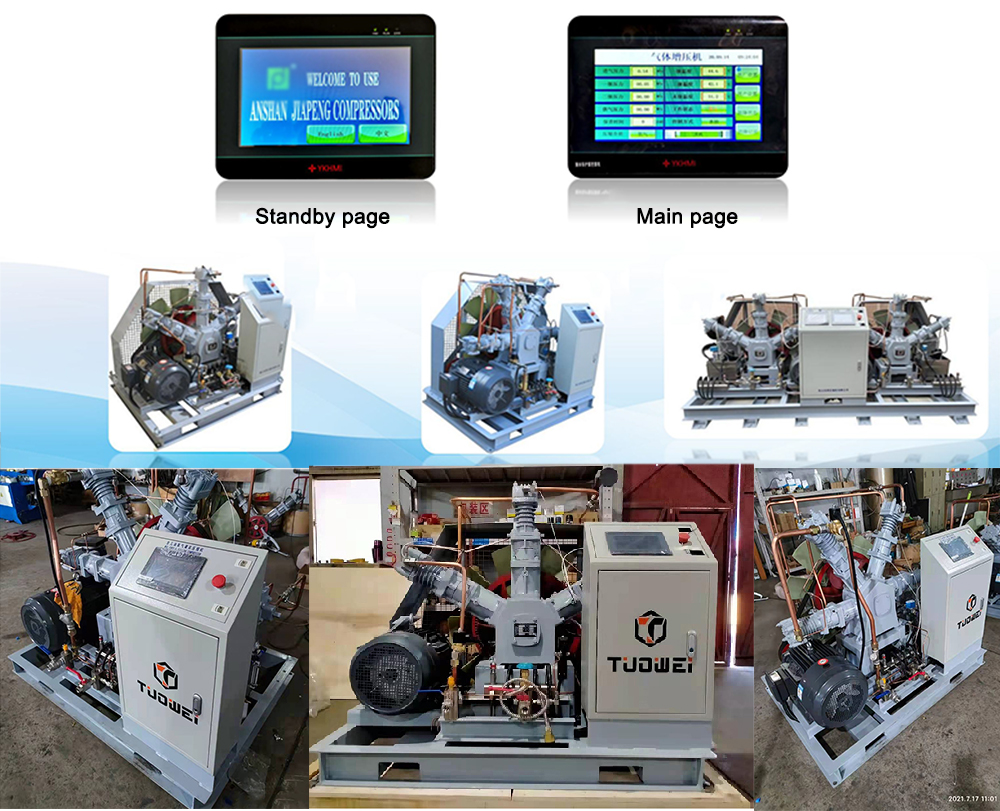

The biggest advantage of this series of oil-free high-pressure nitrogen booster compressors is safety and reliability. 100% oil-free, that is, the whole machine is completely oil-free. No pollution to the compressed medium, simple control, automatic working system, no leakage, and convenient maintenance are the reasons why customers choose.

Oil Free High Pressure Nitrogen Compressor N2 Booster Compressor

Technical Parameters:

Displacement: 5 ~ 140Nm3/h

Inlet pressure: 2~4bar adjustable

Exhaust pressure: 15/20mpa (150/200 bar)

Cooling method: air cooling, water cooling

Product Description:

Oil-free oxygen booster compressor is dedicated to oxygen bottle washing

Product Parameter

!!If there are technical parameters that require greater displacement, please send me a message!!!

Company Information

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

10hp to 175hp Permanent Magnet Frequency Conversion Energy Saving Screw Air Compressor Read More

7.5Kw To 250 Kw Electric Direct Drive Rotary Screw Air Compressor Read More

11kW 15HP 16bar Combined Rotary Screw Air Compressor with Dryer, Air Tank for Laser Cutting Machines Use Read More

Silent Aircompressors Oilless Oil Free Belt Driven Scroll Air Compressor for Sale Read More

185CFM Diesel Portable Mining Screw Air Compressor Read More

© Copyright: 2026 Aircompsupplier All Rights Reserved.

IPv6 network supported

Friendly Links :

Solar Pile Driver